| |

|

|

Choice of paper

cutting machine |

|

|

Inquiries

Inquiries are welcome. Contact us

by phone, by fax,

or by e-mail.

|

|

|

|

|

|

|

|

|

|

|

Wood

Wood paper for laminated plywood |

Wood

The material is cork |

Wood

CFN |

Paper and

paper craft

Paper |

Paper and

paper craft

Packing |

Paper and

paper craft

Twisted paper string ornament |

Paper and

paper craft

Hard press board |

|

|

|

|

|

|

|

Felt

Wool felt |

Felt

Saran rack filter |

Felt

Cloth felt |

Plastic

Plastic cardboard |

Plastic

Polyester film |

Plastic

Paulownia |

Plastic

CFRP |

|

|

|

|

|

|

|

Urethane

Urethane resin |

Urethane

Urethane foam |

Rubber

Rubber |

Vinyl

Soft vinyl sheet |

Glass fiber

Glass fiber mat |

Metal

Metal deposition sheet |

PS board

PS board mat |

|

|

|

|

|

|

|

Honeycomb

Honeycomb |

|

|

|

|

|

|

|

|

|

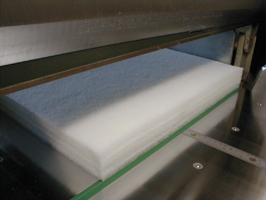

Workpiece (material to be cut):Felt, non-woven fabric, filter |

|

|

|

Cutting case, company G

| Material to be cut: |

Wool felt (18mm thick), air filter, brush material, non-woven fabric |

| Cutting machine: |

eRC-137DX |

|

【Key points of cutting】

| Material and angle of cutting edge |

High-speed steel 21-23° |

| Setting method |

Same as paper. A roll-shaped material should be processed in a flat shape in advance and loaded from the front, or the roll should be set at the rear of the leveling block and drawn toward the front to cut. |

| Clamp (pressing method) |

Gently press |

| Pressure |

4KN |

| Angle at which the cutting edge is lowered |

Standard |

| Method of clamping the cut material |

Immediate release |

| Others |

|

|

|

|

|

Workpiece (material to be cut):Felt, needle |

|

|

Cutting case, company H

| Material to be cut: |

Felt, max. 20mm thick |

| Cutting machine: |

JAC-160CFC |

|

【Key points of cutting】

| Material and angle of cutting edge |

High-speed steel 21-23° |

| Setting method |

Same as paper. A roll-shaped material should be processed in a flat shape in advance and loaded from the front, or the roll should be set at the rear of the leveling block and drawn toward the front to cut. |

| Clamp (pressing method) |

Gently press |

| Pressure |

8KN high/low switching provided, 2KN in case of low pressure. |

| Angle at which the cutting edge is lowered |

Standard |

| Method of clamping the cut material |

Immediate release |

| Others |

|

|

|

|

Workpiece (material to be cut):Vinyl, non-woven fabric |

|

|

Cutting case, company R

| Material to be cut: |

Non-woven fabric |

| Cutting machine: |

JAC-160NFC |

|

【Key points of cutting】

| Material and angle of cutting edge |

High-speed steel 23° |

| Setting method |

Because the material is large, connect an auxiliary table in front of the leveling block to feed. |

| Clamp (pressing method) |

The clamp pedal is not used. |

| Pressure |

6KN |

| Angle at which the cutting edge is lowered |

Standard |

| Method of clamping the cut material |

Immediate release |

| Others |

Low knife speed control with inverter |

|

|

|

Low knife speed control with inverter |

|

|

Cutting case, company V

| Material to be cut: |

saran rack filter Filter element used for filter, etc. |

| Cutting machine: |

eRC-137DX |

|

【Key points of cutting】

| Material and angle of cutting edge |

High-speed steel 21-23° |

| Setting method |

Same as paper. A roll-shaped material should be processed in a flat shape in advance and loaded from the front, or the roll should be set at the rear of the leveling block and drawn toward the front to cut. |

| Clamp (pressing method) |

block and drawn toward the front to cut. |

| Pressure |

4KN |

| Angle at which the cutting edge is lowered |

Standard |

| Method of clamping the cut material |

Immediate release |

| Others |

|

|

|

|

|

|